FAQS

Here are some of the Beryllium copper spring Faqs.

Not Found Your question? Feel free to contact me.

Quotation problems of the product

-

Q: Under which circumstances does our company not charge or return the tooling fee? A: under one of the following circumstances, our company will not charge or return the mold fee:

The customer places an order for a specified quantity of products.

If the customer orders a certain quantity within the agreed time, our company will refund after receiving (able to be deducted from the payment).

Those we think can be promoted as a standard part of the product. -

Q: What is the procedure of our product quotation? A: After receiving non-standard drawing or sample from customers, Our engineering department will provide the following things for analysis.

1. materials

2. manufacturing technique (including electroplating and post-procedure)

3. dimensional tolerance

4. way of measurement

5. package of product, etc -

Q: How long are we able to offer quotation after receiving customers' drawings or samples? A: If there is no mistake on your drawing, our company usually provides official quotation in 2 hours.

-

Q: What if there are some problems on customers' drawings regarding quantity production? A: Our engineering will offer amending advice and then hand over to customers to further confirm, making discussions about relevant problems.

-

Q: What if customers only have a sample without the drawing? A: Customers is expected to send your sample to our company and our quality department will carry out overall dimension measurement.

Then our engineering department will provide the drawing to con firm again with customer.

How to design compression amount

-

Q: The compression of beryllium copper spring is an important parameter for customers to choose. How to choose the compression, mainly consider the following: A: 1. Product resilience: If the compression is too large, theBeryllium copper spring will fail.

2. Compression force requirements: Consider appropriate pressure.

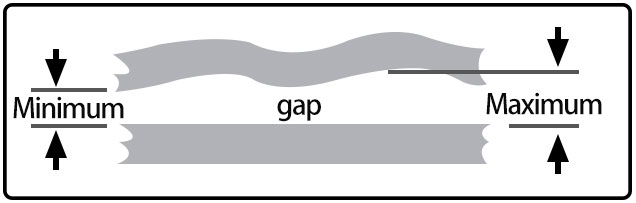

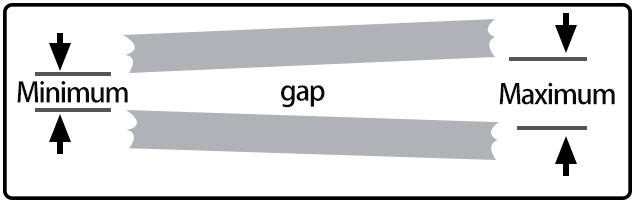

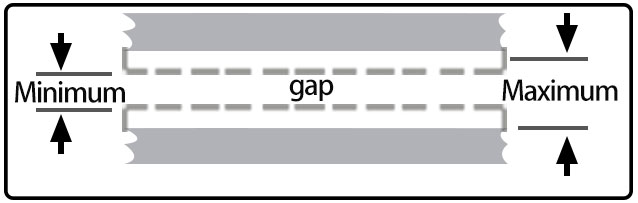

The purpose of shielding is to occupy and cover the existing gap between two uneven surfaces, which is mainly caused by product flatness, manufacturing tolerances and uneven product arrangement.

Surface irregularities

Surface misalignment

Manufacturing tolerance

Compression amount = maximum clearance - minimum clearance

-

Recommendation: According to the statistics of large quantities, The best amount of compression is: 30% (That is, compress to 70% of product height).

Reasonable range of use: 30%-50%

Problems on product structure

-

Q: what is the structure design basis of our standard BeCu Fingerstock? A: BeCu Fingerstock enjoys a strong substitutability, our standard products refer to the universal standard of BeCu Fingerstock to ensure reasonable structure and shielding performance.

-

Q: How to calculate the length of product? A: length of product: L= pitch* pitch nodes- slot width. Due to the special shape of the product, try to take integer times of sections (Eg.MB-1216-01. Length:L=4.75*86-0.45=408mm)

-

Q: In the remarks column, which production process does the softening process belong to? A: due to the characteristics of product structure and customers choose thinner material products, we need to soften the product of normal thickness (our company turns MB-1XX-01 into MB-2XX-01) to reduce the compression force.

-

Q: Why not use products of softening technology? A: the softening technology is the use of chemical treatment method. After treatment, the thickness of the softening is not uniform. If not electroplated, the surface will be dirty, etc, affecting its appearance.

-

Q: Why couldn't the thickness of BeCu Fingerstock be over 0.5mm? A: since BeCu products need heat treatment whose hardness could reach more than 373HV after treatment. If it is two thick with more compressing force, there will be no elasticity and the lose the best advantage of BeCu fingerstock &gasket.

-

Q: Why is the MB-1535-01 able to make the rolling materials for 7.62 meters, while the MB-1640-01 could only make a maximum of 406mm? A: MB-1535-01 belongs to continuous tooling production, while MB-1640-01 needs single engineering bending and the product only be straight. If it is over 406mm, the tooling manufacture processing will be difficult and the sizes will be unstable, resulting in the instability of product.

-

Q: Why are the standard lengths of our products mostly 406mm, 610mm and 7.62m? A: Beryllium copper shielding materials were first used in Europe and the United States, following the British system. The corresponding lengths are 16 inches, 24 inches and 25 feet.

-

Q: We have more than 20 standard products of Fingerstock in shielding room of our company. Can we also make special structure for customers? A: yes, Our company can make appropriate adjustments to our toolings according to customers' needs, and then we can make the product structure required by customers.

Problems on Berryllium copper raw materials. -

Q: MB-1396-01 is specially designed for civil air defense shielding. What is its design basis? A: This product has been produced for more than 10 years. It is specially customized for civil air defense system customers and can meet the shielding requirements of civil air defense projects. The longest length can be 610mm.

-

Q: MB-1756-01 and MB-2756-01 look the same, what is the difference? A: MB-1756-01, material thickness: 0.089mm; MB-2756-01, material thickness: 0.05mm; the atter is much softer than the former, the others are similar.

-

Q: MB-1116-01 and MB-1721-01 look the same, what's the difference? A: MB-1116-01 R1 size is 0.5mm, MB-1721-01 R1 size is 0.95mm, the former is suitable for 1.0mm thick board, the latter is suitable for 1.5mm thick board.

Raw material issues

-

Q: Where do our raw materials come from? A: Our company mainly uses American Brushwellman raw materials: Raw material specifications: C17200-1/4H or 1/2H; but the hardness after heat treatment is above 373HV; The average hardness after heat treatment of our company is: 390HV.

-

Q: What is the hardness of American raw materials? A: Common thicknesses are: 0.05mm; 0.06mm; 0.08mm; 0.089mm; 0.10mm; 0.127mm; 0.15mm; 0.2mm; 0.25mm; 0.3mm; 0.4mm and 0.05m.

-

Q: What are the performance advantages of American materials? A: a. The material thickness is uniform; b. The material hardness is uniform; c. The material appearance is clean; therefore, the product produced has good consistency. Therefore, except for stripping and packaging, it is generally exempted from inspection.

-

Q: What is the status of American beryllium copper material C17200? A: C17200 is a high-beryllium material, with a beryllium content of 1.8-2.0%.

-

Q: Why can't we heat treat first and then stamp? A: Because the reed has bending dimensions, if the hardness after heat treatment is 393HV, it cannot be formed due to excessive resilience; the lower the hardness, the easier it is to form, such as: 0.05mm and 0.06mm is C17200-1/4H. 0.08mm is generally 1/2H.

Production process problems

-

Q: How long is the cross cycle of our mold? A: Our company has professional tooling design engineers and tooling manufacturing master. The general circle is 16 days and that of the complex products is no more than 20 days.

-

Q: What is the tooling manufacturing process? A: It takes 16 days to make the tooling since the tooling manufacturing process is: product drawing conversion -- tooling design -- template procurement and processing -- template heat treatment -- grinding plane -- wire cutting -- assembling molds -- testing toolings -- testing samples (If there is a problem, the mold needs to be corrected).

-

Q: Why do stamping products add stamping oil? A: Our company mainly uses Castrol environmentally friendly stamping oil. a. Lubrication b. Can quickly remove the heat generated by friction.

-

Q: What is the status of American beryllium copper material C17200? A: C17200 is a high-beryllium material, with a beryllium content of 1.8-2.0%.

-

Q: What are the commonly used materials in the production of BeCu Spiral Tube? A: Generally, stainless steel, tin-plated beryllium copper and other metal materials are used to make the spiral tube part. If it is a curled spiral shielding strip, a foamed chloroprene rubber strip with adhesive backing will also be used; if it is a high-performance shielding strip, a solid silicone rubber strip or a fluorosilicone rubber strip will be used to connect with the spiral tube.

-

Q: What is the production process of BeCu Spiral Tube? A: 1. Material preparation (cutting. pre-treatment).

2. Spiral winding (heating. winding. cooling).

3. Bonding of liner to pipe wall (hot melt or chemical bonding).

4. Post-processing (trimming. curing). 5. Quality inspection (dimensions. sealing. strength test). -

Q: What materials are commonly used for electromagnetic shielding braided wire gaskets? A: uch as tinned copper clad iron, tinned phosphor bronze, aluminum, monel (nickel- copper alloy), etc., which have good conductivity and elasticity.

-

Q: What is the production process of electromagnetic shielding braided wire gaskets? A: 1. Material preparation: Select metal wire and elastomer, and perform surface treatment (such as plating).

2. Weaving molding: Weave the metal wire into a mesh structure to form a spring -shaped connecting ring.

3. Combined processing: Combine the metal wire mesh with the elastomer to form a double-layer or multi-layer structure.

4. Post-processing: Perform surface protection treatment (such as coating an anti- oxidation layer), and perform size trimming and performance testing.

-

Q: Why does our company MB-1078 cut off 4 small edges once? (it is the same of other similar products) A: a. able to be changed to continuous tooling stamping; b. able to ensure the consistency of product size; c. able to make the length over 610mm; d. able to make rolling materials.

-

Q: why do we choose 3M9469 tape fixed products? A: In order to ensure the comprehensive performance of the tape, our company selects the tape consistent with the original design in the United States, and orders the tape from the same supplier.

-

Q: Why the slot width on the product should be greater than 0.5mm? A: Because if BuCu is not heat treated, the material will be soft. The hole is small and long, which makes it easy for container to be blocked and the punch is easy to break.

-

Q:The heat treatment insulation is 600F, can you change it? A: It is the best heat treatment temperature provided by the American material factory and our company cannot change it;

-

Q: Why can't the length of the product exceed 610MM after heat treatment? A: Our company adopts high vacuum heat treatment furnace. However, affected by the effective area of processing, the maximum length cannot exceed 660mm, and we generally chose 610mm (24inch).

-

Q: What is the difference between tin plating and nickel plating on the product surface? A: Bright tin plating and nickel plating are both common plating methods. They are also effective ways to prevent product oxidation. HUAWEI requires common tin plating for products and ZTE requires common nickel plating for products. The tin plating film thickness is generally 5-7.5um, while the nickel plating film thickness is 3-5um.

-

Q: What are the ways of our electroplating price? A: hanging plating and bulk plating. In order to ensure product quality, we generally choose to hanging plating (although the cost is much higher).